WHY CHOOSE A DOUBLE SPINDLE LATHE?

Date: 2024-05-29From: SUNTROI

MACHINERY

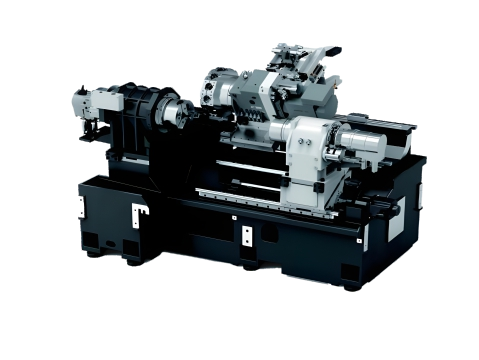

The twin-spindle lathe is a multi-purpose machine that allows, in addition to turning parts of complex configuration such as shafts and flanges, milling and threading. The presence of an anti-spindle provides full double-sided machining of parts.

The EL-550TMSY double-spindle turning and milling machine is a machine from OMA with advanced technology that significantly improves machining efficiency.

- Complete the front and back machining of the parts in one clamping process, ensuring coaxiality and parallelism.

- Reduce manual clamping errors, reduce scratches caused by sequence transfer, save labor,

improve qualification rate and efficiency.

- High-precision heavy-duty linear roller guideway on the X,Y, Z axis allows the axis to maintain high positioning accuracy during rapid movement.

- High speed and ultra high precision THK ball screw.

- The assembly method of the pre-drawn double nuts eliminates the movement gap and keep the accuracy.

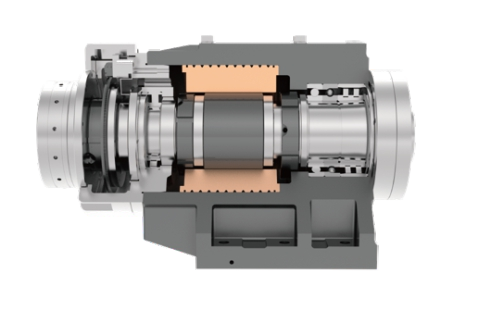

- Built in, mid drive design, compact structure,high efficiency,

low vibration, and high precision,achieving

high-speed and precision cutting.

- The spindle runs more smoothly at high speeds and has shorter acceleration and deceleration times. The service life of spindle bearings is long.